Testador de solidez de cor em conformidade com os padrões da série ISO 105

A solidez da cor refere-se à capacidade de um tecido de resistir ao desbotamento ou à descoloração quando submetido a diversos fatores externos durante o processamento, uso ou armazenamento, como atrito, lavagem, exposição à luz ou transpiração. Produtos com baixa solidez da cor são propensos à perda de cor ou transferência para outros itens, comprometendo a aparência e a qualidade. Tais problemas podem até representar riscos potenciais à saúde devido à migração de tinta.

Série ISO 105: Padrões de solidez de cores têxteis

Os testes de conformidade com a série ISO 105 constituem o padrão internacional para avaliar o desempenho da solidez da cor têxtil. Esses testes avaliam a capacidade de retenção da cor de um tecido sob diversas condições ambientais. Essas avaliações são cruciais para garantir a estabilidade da cor durante a lavagem, atrito, exposição à luz, transpiração e condições semelhantes, impactando diretamente a qualidade do produto, a durabilidade e a satisfação do consumidor.

O que torna a ISO 105 particularmente valiosa é sua abordagem granular à avaliação da solidez da cor. Cada subseção isola desafios ambientais específicos:

-

Série B: Resistência à luz e às intempéries

-

Série C: Resiliência na lavagem e lavagem

-

Série E: Resistência à água e à transpiração

-

Série X: Vários fatores mecânicos (fricção, etc.)

Testador de solidez de cor de acordo com a série ISO 105

Princípio

A solidez da cor é uma exigência importante e se refere à resistência da cor ao desbotamento ou desbotamento de materiais têxteis tingidos ou estampados a vários tipos de influências, incluindo água, luz, fricção, lavagem, transpiração, etc., às quais são normalmente expostos durante a fabricação têxtil e no uso diário.

Métodos de teste padrão: alguns exemplos

Solidez da cor à luz

A ISO 105-B01:2014 especifica um método destinado a determinar a resistência da cor de tecidos de todos os tipos e em todas as formas à ação da luz do dia.

A ISO 105-B02:2013 especifica um método destinado a determinar o efeito na cor de tecidos de todos os tipos e em todas as formas da ação de uma fonte de luz artificial representativa da luz natural (D65). O método também é aplicável a tecidos brancos (branqueados ou opticamente clareados).

Esta máquina é aplicada em testes de resistência à luz, resistência à transpiração, resistência à luz e ao suor e envelhecimento à luz de tecidos, tintas, corantes, revestimentos, borracha, plástico, pisos de madeira, papel e outros materiais. Ela tem funções anticlimáticas de exposição à chuva, revolução e pulverização de névoa.

Padrões da máquina de teste de resistência à luz GESTER:

GB/T 8427, GB/T 8430, GB/T 14576, GB/T 15102, GB/T 15104,

ISO 105-B02/B04

, ISO 12040, ISO 11341,

ATCC TM 16, AATCC 169, ASTM D5010, ASTM D4303,1, JIS L0843, M&S C09/C09A

Solidez da cor à lavagem

A ISO 105-C06:2010 especifica métodos destinados a determinar a resistência da cor de têxteis de todos os tipos e em todas as formas a procedimentos de lavagem doméstica ou comercial utilizados para artigos domésticos comuns com um detergente de referência. Artigos industriais e hospitalares podem ser submetidos a procedimentos especiais de lavagem, que podem ser mais severos em alguns aspectos. A perda de cor e manchas resultantes da dessorção e/ou ação abrasiva em um único teste (S) aproximam-se bastante de uma lavagem comercial ou doméstica. Os resultados de um teste múltiplo (M) podem, em alguns casos, ser aproximados pelos resultados de até cinco lavagens domésticas ou comerciais a temperaturas não superiores a 70 °C. Os testes M são mais severos que os testes S devido ao aumento da ação mecânica.

Este testador de resistência à lavagem é usado para testar o grau de mudança de resistência da cor de tecidos tingidos após a lavagem. Ele não apenas faz o teste de resistência da cor à lavagem, mas também o teste de resistência da cor à lavagem a seco.

Testador de resistência à lavagem GESTER

Padrões:

ISO105-C01, C02, C03, C04, C05, C06, C08, C09, C10, D01, E03, E12

GB/T 5711, GB/T3921-1 a 5, GB/T12490; AATCC 3, 61, 62, 86, 132, 151, 190

JIS L0860, JIS L0844, JIS L0879; M&S C4A, C5, C37, P3B; BS 1006 PRÓXIMO 2,3,5

IWSTM 7.115.177.193, 240, 241; FTMS 191 Método 5610/5622

Solidez da cor à transpiração e saliva humanas

A ISO 105-E04:2013 especifica um método para determinar a resistência da cor de tecidos de todos os tipos e em todas as formas à ação da transpiração humana.

A ISO 20701 | IUF 427:2017 especifica um método para determinar a solidez da cor à saliva de todos os tipos de couro, independentemente do procedimento de coloração aplicado. O método utiliza uma solução de saliva artificial para simular se os materiais corantes podem migrar do couro para a boca ou para as membranas mucosas.

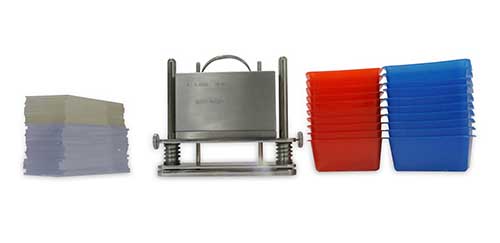

O testador de transpiração GT-D09 é usado para testar a resistência à transpiração e a solidez da cor de todos os tipos de materiais têxteis e tingimento, tecidos coloridos e testar sua resistência à transpiração, à prova d'água, resistência à água do mar, resistência à saliva, resistência a alvejantes de cloro, resistência a etamsilato e outros desempenhos.

Testador de transpiração GESTER

Padrões:

Transpiração

GB/ T 3922, AATCC 15,

ISO105-E04

, JIS L 0848, ISO 11641

Água do mar

GB/ T5714,

ISO105-E02

, AATCC107

Água

GB/ T5713,

ISO105 E01

, AATCC106

Saliva

GB/ T 18886

Solidez da cor à fricção

A ISO 105-X12:2016 especifica um método para determinar a resistência da cor de tecidos de todos os tipos, incluindo revestimentos têxteis para pisos e outros tecidos felpudos, à abrasão e manchas em outros materiais. O método é aplicável a tecidos feitos de todos os tipos de fibras na forma de fio ou tecido, incluindo revestimentos têxteis para pisos, tingidos ou estampados. Podem ser realizados dois testes: um com um pano seco e outro com um pano úmido.

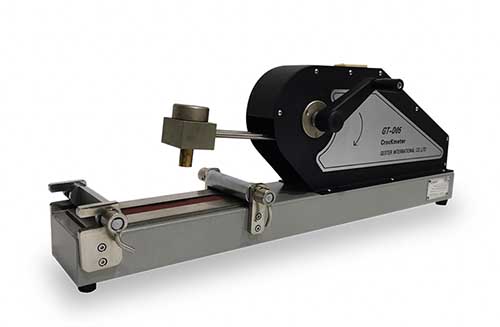

O Testador de Solidez de Borracha Crockmeter é usado para determinar a solidez da cor de tecidos à fricção seca ou úmida. Um suporte de amostra de acrílico com pinos garante a rápida montagem da amostra e a repetibilidade dos resultados.

Padrões do Crockmeter GESTER AATCC:

BS 1006-D02,

ISO 105-X12/D02

, M&S C8, AATCC 8/165, ASTM D6279, JIS L 0849 Tipo1, JIS L 0862 Tipo1